Stay compliant and safe – Book your PSSR2000 Inspection today.

Our PSSR2000 Inspection Service ensures that your coffee machine’s pressure vessel is compliant with the Pressure Systems Safety Regulations 2000, reducing the risk of accidents, breakdowns, and costly repairs. With our professional inspections, you can operate with confidence and peace of mind.

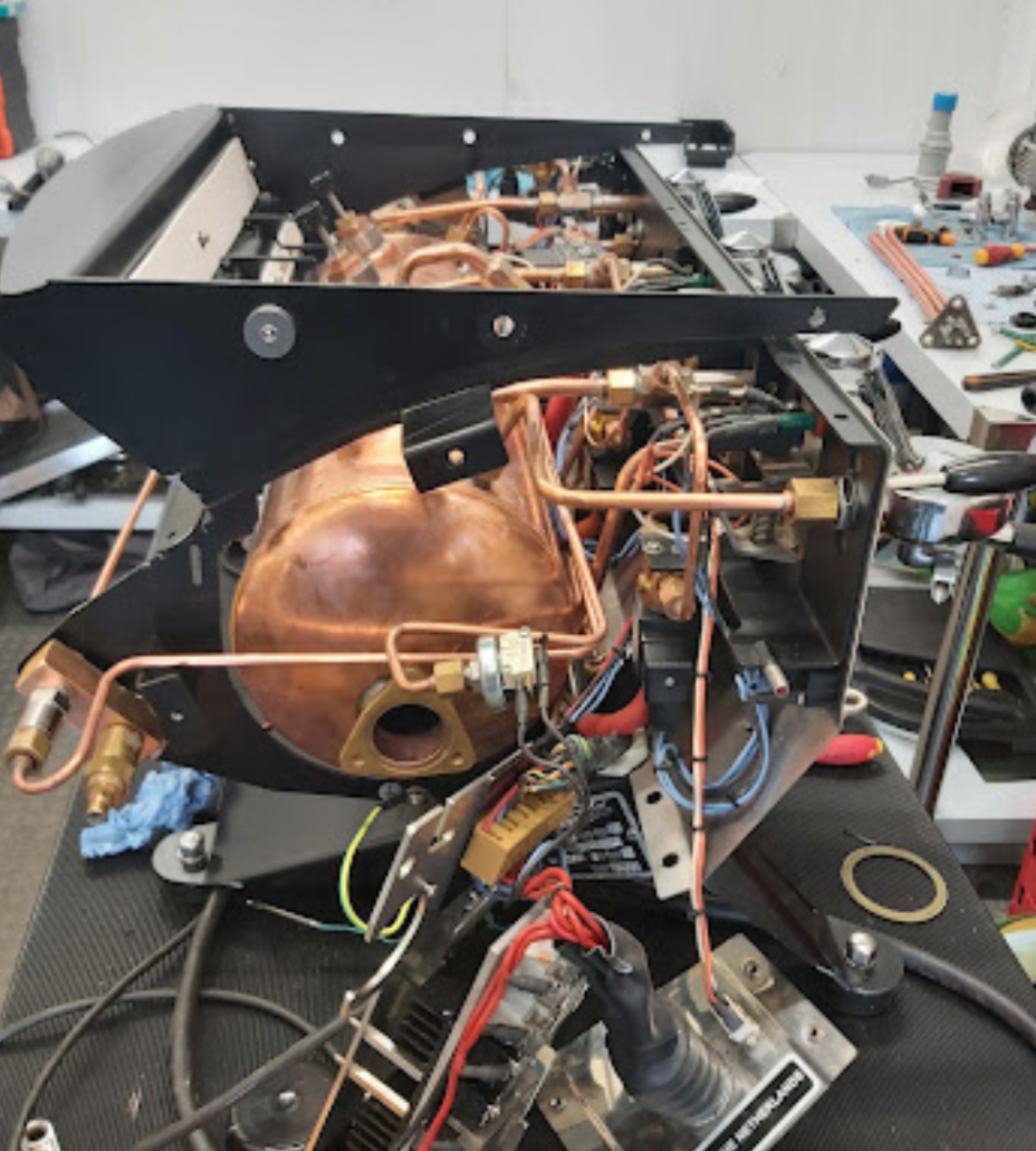

PSSR2000 BOILER PRESSURE VESSEL INSPECTION

Comprehensive pressure vessel inspection

At ALL4COFFEE, we understand the importance of safety and compliance when it comes to operating commercial coffee machines. PSSR2000 Boiler Pressure Vessel Inspections are not just a legal requirement; they are essential for maintaining safe and efficient operation.

Our certified engineers provide a thorough examination of your coffee machine’s pressure vessel, including:

- Internal and External Visual Inspection – Checking for corrosion, leaks, or structural damage

- Pressure and Safety Valve Testing – Verifying functionality and ensuring proper release mechanisms

- Boiler Integrity Checks – Assessing the condition of the boiler shell, welds, and joints

- Steam and Water System Examination – Ensuring safe and efficient steam flow and water circulation

- Operational Safety Checks – Testing pressure gauges, thermostats, and safety controls

We use advanced diagnostic tools to identify potential issues before they lead to costly repairs or safety hazards.

PROTECT YOUR BUSINESS & CUSTOMERS

What is PSSR2000?

PSSR2000 stands for the Pressure Systems Safety Regulations 2000, a legal requirement in the UK designed to ensure the safety and integrity of pressure vessels, including those used in commercial coffee machines.

These regulations mandate that any equipment containing pressurised steam or hot water must be:

- Inspected regularly by a qualified engineer

- Maintained in safe condition to prevent accidents or malfunctions

- Documented with a Written Scheme of Examination (WSE)

Failure to comply with PSSR2000 can result in legal penalties, operational disruptions, and safety risks.

Working with top-quality brands

Frequently asked questions

What is PSSR2000, and why is it important?

PSSR2000 stands for the Pressure Systems Safety Regulations 2000, a legal requirement in the UK designed to ensure the safety and integrity of pressure vessels, including those used in commercial coffee machines. It is important because it helps prevent accidents, equipment failure, and potential safety hazards by mandating regular inspections and maintenance of pressure vessels containing pressurised steam or hot water. Compliance with PSSR2000 is essential to meet legal requirements, ensure operational safety, and maintain insurance coverage.

Which coffee machines require PSSR2000 inspection?

PSSR2000 inspections are required for commercial coffee machines that use pressurised steam boilers or hot water boilers. These are typically found in traditional espresso machines and other commercial coffee equipment designed to maintain high-pressure hot water for brewing. We specialise in inspecting pressure vessels for leading coffee machine brands, including La Marzocco, Victoria Arduino, Nuova Simonelli and Conti Monaco. We do not inspect domestic coffee machines or other types of pressure vessels.

How often should PSSR2000 inspections be conducted?

The frequency of PSSR2000 inspections depends on the manufacturer’s recommendations, usage levels, and the condition of the equipment. Typically, high-usage environments such as busy cafés and coffee shops require annual inspections, while moderate usage locations may require biannual inspections. Custom schedules can also be set based on the equipment’s operational requirements and condition. Our team provides tailored inspection schedules to ensure compliance and safety.

What happens during a PSSR2000 inspection?

During a PSSR2000 inspection, our certified engineers perform a comprehensive examination of the pressure vessel, including internal and external visual inspections for corrosion, leaks, or structural damage. We also test pressure and safety valves, check the integrity of the boiler shell, welds, and joints, and examine steam and water systems to ensure safe and efficient flow. Operational safety checks are conducted on pressure gauges, thermostats, and safety controls. Our inspections are thorough, ensuring all safety aspects are covered.

What is a Written Scheme of Examination (WSE)?

A Written Scheme of Examination (WSE) is a mandatory document required by PSSR2000, detailing the inspection frequency and procedures specific to the pressure vessel. It includes examination schedules, tailored procedures based on the machine’s design and operational requirements, and compliance documentation to demonstrate regulatory adherence. The WSE is customised for each coffee machine and is necessary for audits and insurance purposes. We provide a WSE with every PSSR2000 inspection to ensure legal compliance.

Do you provide certification after the inspection?

Yes, after completing the PSSR2000 inspection, we provide a Certification of Compliance that confirms your equipment is safe and compliant with the Pressure Systems Safety Regulations 2000. We also provide a detailed inspection report outlining our findings, recommendations, and any required repairs or adjustments. This certification and report serve as official documentation for regulatory compliance and insurance requirements.

What if issues are found during the inspection?

If any issues are identified during the PSSR2000 inspection, our engineers will inform you immediately and provide detailed recommendations for corrective action. In most cases, we can carry out the necessary repairs or adjustments on-site, as our technicians carry an extensive inventory of genuine spare parts. If more extensive repairs are needed, we will arrange a follow-up visit or recommend a workshop service. Our priority is to ensure safety, compliance, and operational efficiency.

How can I schedule a PSSR2000 inspection?

You can schedule a PSSR2000 inspection by contacting us through our website, phone, or email. Our team is ready to assist you with the booking process, provide detailed information about the inspection, and answer any questions you may have. We offer flexible scheduling options to minimise disruption to your business and ensure compliance with safety regulations.